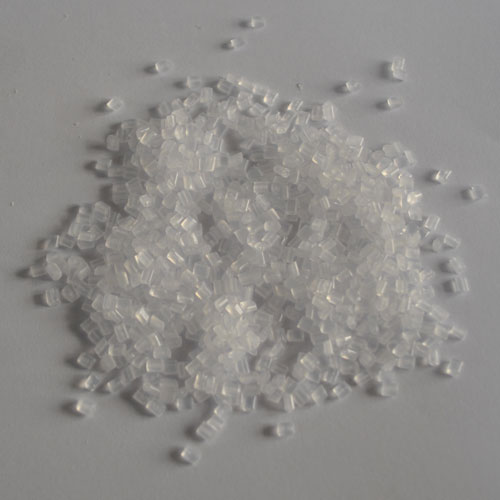

Cooling master batch mainly used to reduce the PP (polypropylene) production and processing temperature of spinning in the plastic products, improve the liquidity of polypropylene, so as to improve the workability, reduce energy consumption.

It will have best effect in PP long, short silk spinning process. At the same time, it is also widely used in PP blown film, woven bag,

monofilament, injection molding, pipe andso on.

The main function of PP cooling master batch:

Add 1%-3% cooling master batch, can make the temperature reduce 10℃~25℃.

Add cooling master batch, can make the extrusion grade PP to produce high quality polypropylene coarse, fine long, short silk, it is

possible to improve the PP blown film, woven bag, plastic injection, pipe and other products quality, can significantly reduce power consumption, improve the efficiency.

Recommended dosage: non-woven spinning: 1.5%~2.0%, spinning: 1.0%~2.5%;